FAQ

Do you have any questions about our Weasyfix foundations screws or our concept?

Below, you can find questions that we are most frequently asked about the foundation screws and other aspects of the Weasyfix concept.

The Weasyfix concept

-

FS XXXX-F screws are suitable for compact, earthy soils and slightly stony soil.

FS 550-F and FS 550 Rock screws are suitable for hard and very hard soil with a stone content greater than 50%.

The FS 1120 FL screw is designed for sandy soil and earthy soil with a very low stone content.

-

In general, 6 main steps are required to install the screws:

1/ checking the site & equipment

2/ plotting the position

3/ making the hole in the ground

4/ locking the adapter

5/ driving in the screws

6/ tips & advice

-

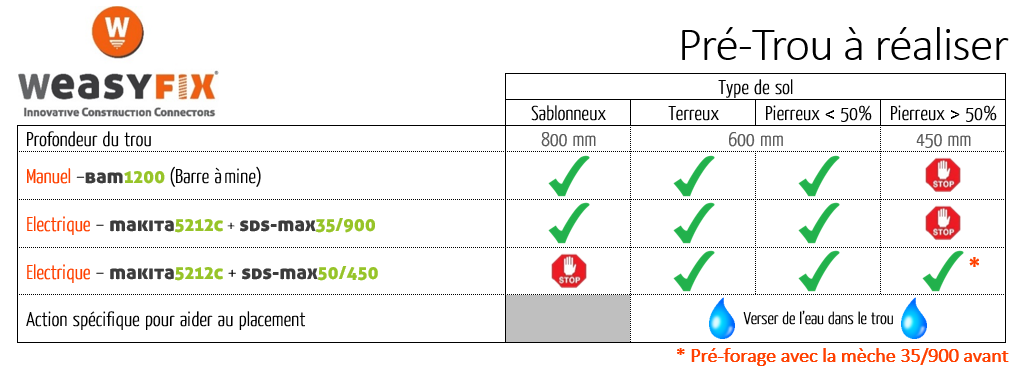

YES!

Whatever the type of soil, it is always risky if you don’t make a hole

in the ground first,

as failure to do so may make the screw move around during installation which

will damage the soil around the screw.

This could force you to install the screw in another location (at a minimum distance of 50 cm) which can be very problematic.

In addition, the hole helps to guide the screw during installation and therefore puts less pressure on the installation machine.

Finally, pouring water into the hole helps to lubricate the position of the screw and therefore to improve its installation.You can adapt the diameter of the hole to the type of soil.

-

-

Here are three ways to calculate the load-bearing capacity of the soil.

They differ in cost, precision and the number of parameters that they take into account.

(Ranked in descending cost order)- Study carried out by a specialized engineering office

- Test carried out by the installer prior to installing the screws

- Assessment by the installer during installation

-

Weasyfix distributes its products exclusively through its stockist partners in order to provide you with a local service.

Apart from being able to source all our products locally, our partners will help you with the technical and quantification aspects of the products involved in your project.

To find out where to get hold of our products, don’t hesitate to get in touch with our technical sales reps whose details can be found on our contact page. -

NO!

Thanks to Weasyfix’s distribution network, you can hire the installation tools you need from our local distributor.

To find out where to find our products, contact our sales rep in your region, whose details can be found on the contact page on our website.

-

YES!

Foundation screws are perfectly suitable for installing in fresh water and sea water.

A distinction must be made here between two cases:

- The installation is carried out in shallow water: an installation machine that does not require a specific tool can be used. As the Toku MI4500 is pneumatic, there is no risk of electrocution.

- The installation is carried out in deeper water: the pneumatic machine must be adapted to the work carried out underwater.

-

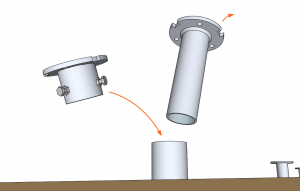

If a screw gets stuck because it is too tall in relation to the ground, the Top 60 (C13) will help you to replace the head of the foundation screw after sawing the tube to the correct height.

-

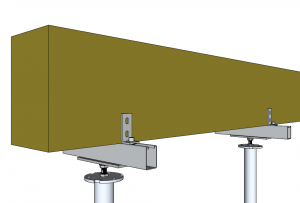

If the structure exerts very high loads on a joist with a large cross-section.

If the floor is made up of frames with large cross-sections placed side by side, you will need to enlarge the connector and reinforce the anchorage in the ground.

Here is an easy and inexpensive solution.

Weasyfix products

-

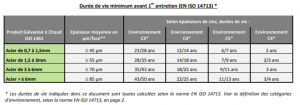

The service life is measured in terms of years before any maintenance of the galvanization is required.

Obviously, this depends on the environment in which the screw is installed.

- In less aggressive environments, the service life is between 35 and 50 years.

- In marine environments, the service life is between 9 and 11 years.

For more information, you can find tables listing the different thicknesses and types of environment below:

-

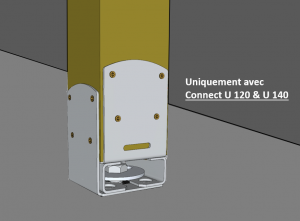

When installing foundation screws, it can occur that one of them may not have been positioned completely vertically.

Wood Pro can be used to correct this slight installation error thanks to a patented procedure based on a correcting EPDM rubber gasket.

See photos:

-

The connectors have a double function:

- They secure the foundation screw and the structure they are supporting.

- They correct any imperfections in the foundation screws’ installation.

Therefore, they must be specific to the types of structure and types of corrections necessary.

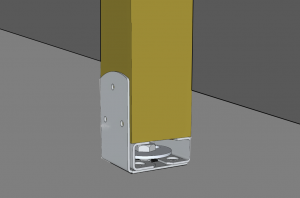

- Wood 90–Wood 120 and Wood 140 connectors are suitable for vertical wooden structures subjected to low lateral forces.

- Connect connectors

U70

–U90

–U120

and

U140

are suitable for vertical wooden structures subjected to higher lateral forces. - Wood basic, Wood basic 3D and Wood Pro connectors are suitable for horizontal structures.

- Connect 51 and Connect 60 connectors as well as top 60 connectors are suitable for galvanized steel structures.

-

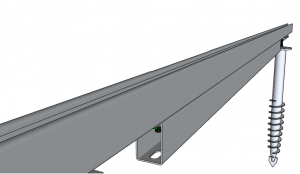

If you need to increase the distance between two foundation screws, for example, due to the presence of a septic tank, you can do so by reinforcing the C profile of the lower structure.

-

By strictly following the four steps illustrated by the symbols, you can install the foundation screws in virtually all types of soil, including very hard soil, and also protect the installation machines.

You will save time if you follow these four steps! -

The WeasyHead must remain attached to the foundation screw until the foundation screw has been driven into the ground in order to transmit all the energy from the installation machine to the foundation screw.

Therefore, ideally, it should be attached using a small impact driver.

If you do not have one, you can use a hand impact driver

hand impact driver

F14.

WeasyHead Fix

.

Options

-

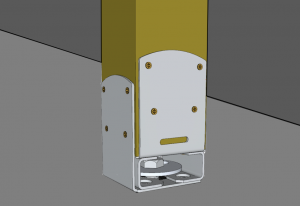

The post is stabilized with the aid of 2 CONNECT U connectors attached directly in the concrete.

Products:

C38.

Connect U 70

/ C31.

Connect U 90

/ C32.

Connect U 120

/ C33.

Connect U 140

-

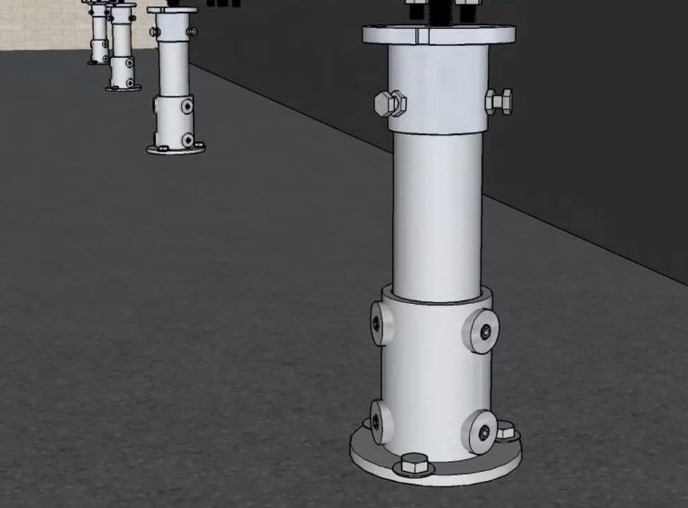

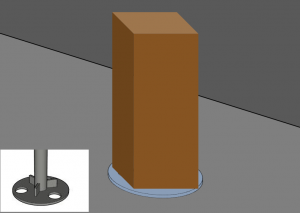

The following option can be used to attach a metal tube to an existing concrete slab.

Products used:

C12.

CONNECT60

/ E3.

TUBE 60/1000

/ C13.

TOP60

-

Find out here how to increase the load-bearing capacity of a C profile?

This can be used to avoid:

- A septic tank

- Electric cables, water inlets or other impediments

- Concrete slabs, rocks and other installation obstacles

-

If you are using primary joists with a cross-section exceeding 140 mm in width, the WoodBasic (C2) and WoodBasic 3D (C3) prevent any further adjustment or alignment.

This problem can be solved with the option shown opposite.

-

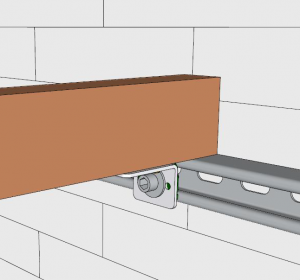

It is also possible to attach your structure to a wall to ensure greater stability.

-

If the screw gets stuck because it is too tall in relation to the ground, the Top 60 (C13) will help you to recreate the head of the foundation screw after sawing the tube to the correct height.

-

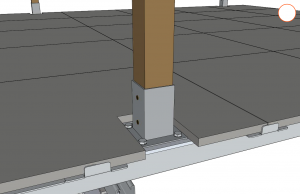

If you wish to install a pergola on your stoneware slab terrace, Weasyfix has the solution that will enable you to build it quickly and aesthetically.

-

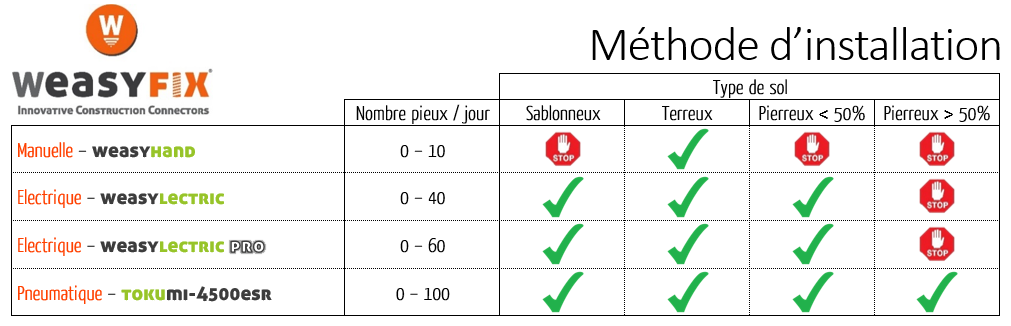

It is possible to install the screws manually in the case of small projects involving a small number of screws.

However, in the event of hard soil or larger projects, we highly recommend using electric tools.

-

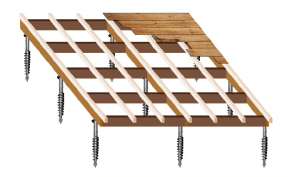

As exotic wood with large cross-sections is rare and expensive, WeasyFix proposes a structural alternative enabling the use of small cross-sections of exotic wood while reducing the number of foundation screws required to ensure an even load distribution.

-

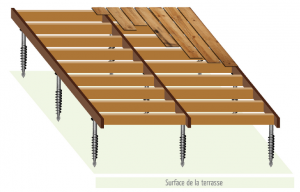

In the case of a structure built very close to the ground, WeasyFix proposes a structural alternative which makes it possible to avoid digging beneath the construction, while reducing the number of foundation screws required for a good load distribution.

-

The post is stabilized with the aid of 2 CONNECT U connectors attached directly in the concrete.

Products:

C32.

Connect U 120

/ C33.

Connect U 140

-

The post is stabilized with the aid of a CONNECT U connector attached directly to the concrete.

Products:

C38.

Connect U 70

/ C31.

Connect U 90

/ C32.

Connect U 120

/ C33.

Connect U 140

-

It is also possible to attach your structure to a wall to ensure greater stability. We highly recommend doing this for raised terraces.

Installation tutorial

Installation tutorial

-

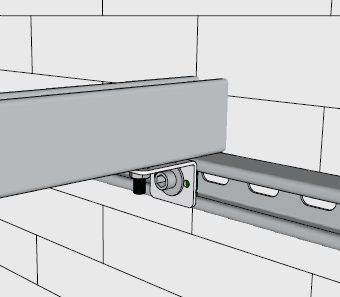

The following option can be used to attach a wooden structure directly to an existing concrete slab.

Products used:

C36.

connect 30-250

-

The following option can be used to attach a wall fastening to a wall which is not at right angles to the direction of the slabs.

-

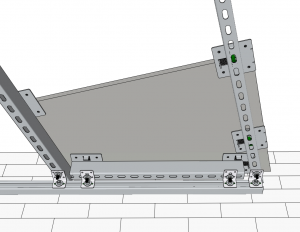

When the shape of the terrace requires the installation of a metal support to support the boards or for the battens, you can use internal joints (C17) to install a C profile as a spacer and therefore support the top structure.

This option is compatible with 100% metal structures and combined metal and wood structures (solution 12/13/14/15/16/17).

See the installation plan below.