solution 41

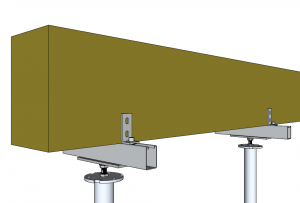

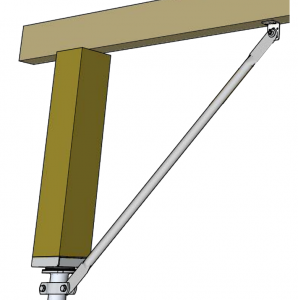

This solution consists of two layers of wooden battens attached to wooden posts which correct any differences in level beneath the structure.

You can combine class 4 pine joists with battens made of exotic wood, for example.

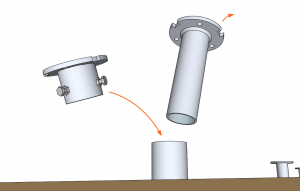

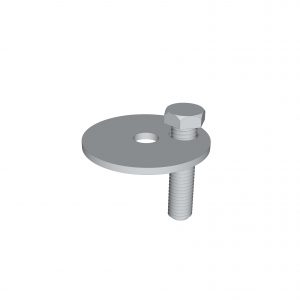

The range of WEASYFIX connectors for wooden posts ensures precise and sturdy positioning.

Advantage 1: A single length of foundation screw is used as the wooden posts compensate for any differences in level.

This makes stock management easier both in the workshop and at the site.Advantage 2: The finish is more aesthetically pleasing than with metal tubes if you do not intend to mount cladding around the construction.

Comprehensive tutorials

Detailed installation

Complementary modules

Options

Our products